Our Technology

The newest technology of phase change material

(PCM) and innovative thermic fabric.

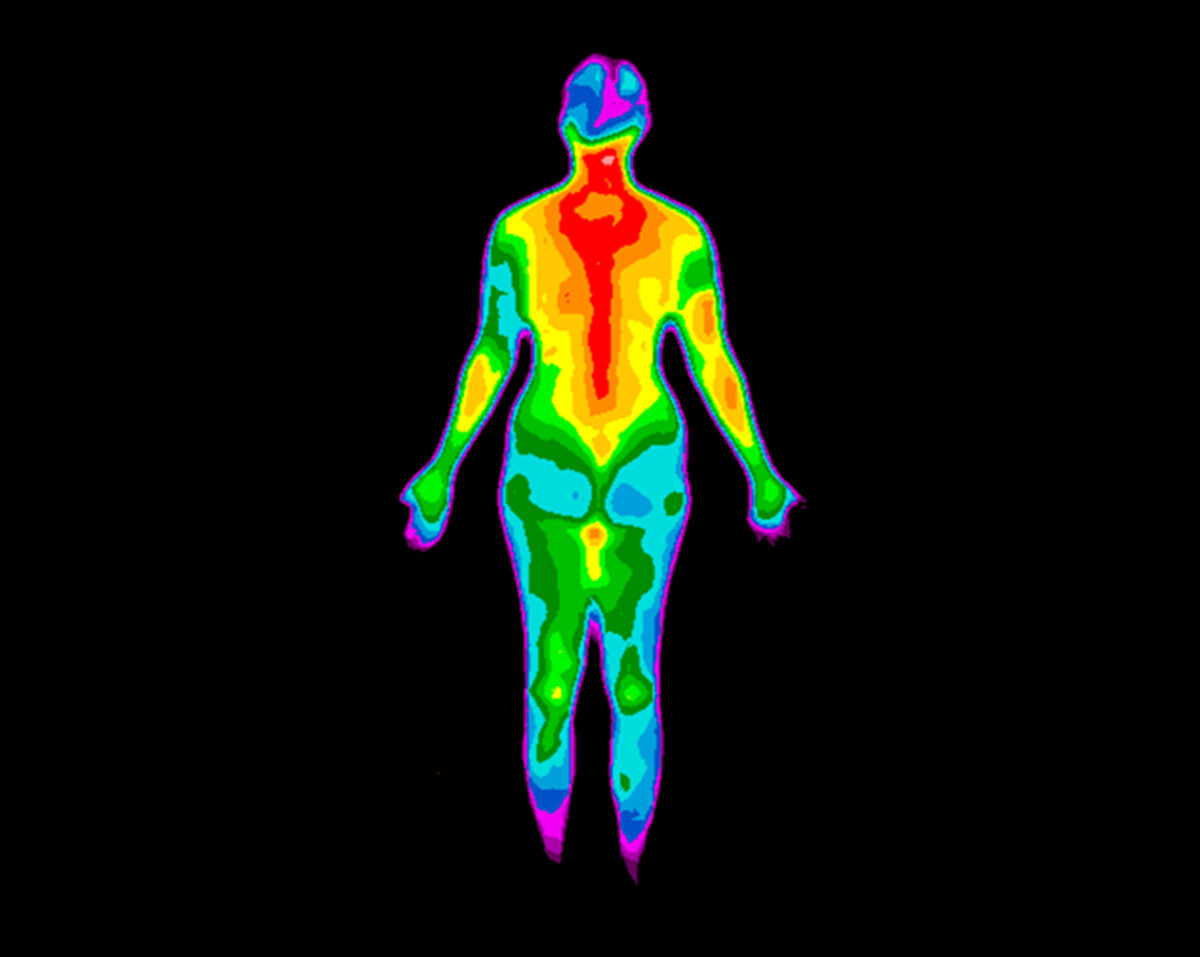

Thermic Mattresses dissipate body heat and allows you to sleep cooler.

Not only can you feel the cool-touch thermic fabric cooling you while you lie on it, the grey fabric actually turns white and leaves an impression, so it is evident that body heat is being dispersed.

Progressive layers of gel memory foam, memory foam, poly foam, and high-density base foam provide incomparable orthopedic support for an exceptional sleep experience.

PCMs can be encapsulated or unencapsulated. Encapsulation provides strength to a PCM.

PCMs are generally available in three forms: unencapsulated raw PCM, microencapsulated PCM and macroencapsulated PCM. The difference between the two encapsulated options is the size of the particle. Inorganic and water-based PCMs cannot be encapsulated

Encapsulation of a PCM adds an outer shell to the PCM core to prevent leakage, degradation and contamination. For a good visual, we often describe it as the candy shell around the chocolate center of an M&M!

Microencapsulated Phase Change Materials come in 3 forms:

PCMs are offered as dry powder, wet cake, and slurry. This allows for multiple uses in a variety of different end products since each form as its own advantages for application or incorporation into or onto other materials.

The uses and benifits for PCMs are endless!

Clothing, mattresses and pillows are just a few examples of where PCMs are used. PCMs provide many advantages when incorporated into products. They include energy savings, a better night’s sleep, cooling and heating relief in remote locations without access to electricity.

Latent heat is crucial for thermal management

There are two kinds of heat energy: sensible and latent. Most traditional heating systems use sensible heat to alter the temperature of a substance. But PCMs use both sensible and latent heat for thermal storage (rather than just temperature change).

The effects of PCMs can last a long time.

During a Thermal Cycle Test, a PCM is frozen and melted multiple times to test its durability. This helps us determine how long the effects of PCMs will work. If a PCM is going into a foam mattress, the expectation is that the cooling effect will last for many many years.

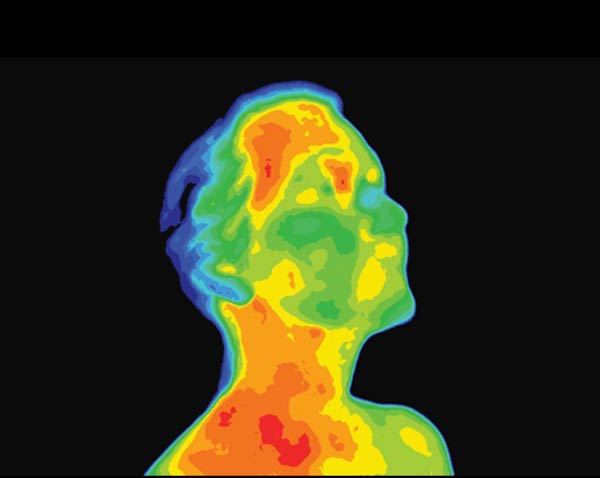

PCMs activate at different temperatures.

PCMs are available with a variety of different points. Differential scanning calorimetry (DSC) is a thermoanalytical technique used to determine the peak melting points and latent heat values of PCMs. This data is very important when deciding how to incorporate PCMs into products. Cool touch fabrics need to active at human body temperature, or around 37c.

Incorporating PCM into our mattresses is a revolutionary way to cool the body during the night which helps you seelp you best.